The mystery of BASE TEMPERATURE (TB)

- Gilles Petit PAUL

- Mar 24, 2024

- 8 min read

Updated: Apr 1, 2024

(and why this is of little interest to a non-professional)

When we browse blogs, groups, amateur bakery forums we quickly see the term " BASIC TEMPERATURE " come up and at the same time we easily understand that controlling temperatures in bakery is fundamental. So let’s dive into this slightly overrated figure together.

"IS THIS CONCEPT REALLY USEFUL FOR AN ENTHUSIAST?

What you must remember

Why this article

Controlling fermentation involves managing the temperature of the dough

The way to influence the temperature of the dough is through the temperature of the water

The method

Base Temperature (TB) is an empirical method for calculating water temperature

The Base Temperature (TB) is a sum of 3 temperatures (Air, Water, Flour)

The implications

The more kneading heats the dough, the lower the base temperature.

The Base Temperature of professional protocols is specific to a bakery

At home for a dough temperature at the end of kneading between 73.4°F and 77°F / 23°C and 25°C

TB kneading with a robot = 147.2 °F / 64°C (4 min kneading V1 / 6 min kneading V2 induced +3 °C heating of the dough)

TB manual kneading = 167 °F / 75°C (no heating of the dough)

My all-digital approach

An Android App “ Homemade bread recipe ”

It is possible to integrate temperatures with fermentation times

At the end of this article you will understand:

The real meaning of this number called “Base temperature” (e.g. 161.6°F / 72°C)

Why temperatures are important in bread making

Alternative methods to better control the temperature of your dough

This article will summarize the origins and technical elements of this "basic temperature" that we see flourishing on all amateur sites without having a deep explanation of this notion that you will quickly understand reserved for professionals.

Base Temperature | the origin and evolution of the concept

Firstly, the Base Temperature (TB) is the sum of the temperatures of the ingredients by significant weight in the bread dough and that of the ambient air.

Depending on the type of bread you want to obtain, the ambient temperature of your room and your time constraints (scheduling), you must adapt the fermentation temperature of the dough (long/short fermentation, manual/mechanized kneading, aromatic power, etc.)

From the wooden mixer , through the Kitchen Aid Artisan and finishing with the semi-professional SANTOS mixer

In the case of a classic fermentation or with very little leaven (Respectus Panis) a dough temperature around 75.2 °F / 24 °C works well. The most easily controllable parameter to influence the temperature of the dough at the end of kneading is the water temperature.

The challenge is therefore to determine this water temperature to obtain around 75.2 °F / 24 °C at the end of kneading. That said, be careful because then the temperature of the place where the dough will ferment will intervene because the dough will converge more or less slowly depending on its weight towards this so-called "ambient" temperature.

Firstly, we focus on the target or desired temperature at the end of kneading which will be our starting point for fermentation.

Empirically, notably with the contribution of Emile DUFOUR in the 1930s, a method was formalized and disseminated to manage the temperature of the dough to calculate the pouring water.

Base Temperature (TB) = sum of the Temperatures of each significant ingredient by weight + Ambient air temperature.

Salt, yeast and sourdough in small quantities are not included because it is an approximation.

TB = Flour Temperature + Water Temperature + Ambient Temperature

The TB is 3 times the temperature of the dough at the end of kneading (can be 4 times if sourdough is added in significant quantities).

Basically by applying the formula this gives 75.2 °F of desired dough temperature .

Ambient temperature of 84.2 °F and the Flour at 77°F

. 75.2 °F x 3 = 225.6 °F = 77 + Water temperature + 84.2

. Water temperature = 225.6 - 77 - 84.2 = 64.4 °C

For a Room temperature of 64.4 °F and the Flour at 60.8 °F

. 75.2 °C x 3 = 216 °F = 60.8 + Water temperature + 64.4

. Water temperature = 216 - 60.8 - 64.4 = 100.4 °C

Now we must integrate other parameters such as kneading. This warms the dough considerably when done in a food processor or long/powerfully by hand..

Use among professionals | it all depends on the problem

In a professional setting with a mechanical dough mixer, dough can increase by 10.8°F to 18°F in 20 minutes of kneading (at 80 revolutions per minute, i.e., 2nd speed).

This temperature measurement during kneading depends on several factors:

Duration of kneading

Rotation speed

Hydration of the dough

The mass of the dough (inertia requires)

The type of mixer (oblique axis, plunge arm or spiral )

The base temperature method has therefore been adapted to integrate the heating of the dough into the kneading.

For a target temperature of 75.2°F, the TB would be 225.6 °F. Now we know that kneading will heat the dough by 9 °F. In this calculation method we subtract 9 °F from the “initial frictionless TB”, which here gives a TB at 216.6 °F.

The formula becomes:

TB = Target temperature - Temperature increase due to friction

= Flour Temperature + Water Temperature + Ambient Temperature

>> Automatic calculation of the Water Temperature with dough kneading friction

Therefore, the more friction increases (duration/intensity of kneading increases), the more the TB will decrease. This is understandable when seeing TB's professional guides for the different types of kneading for 64% hydration (example of training course).

Spiral dough mixer

158°F/ 70°C for slow speed kneading (PVL) - 15 min 1st speed

140°F / 60 °C for improved kneading (PA) - 8 min 1st speed / 3 min 2nd speed

129.2°F / 54°C for intensified kneading (PI) - 5 min 1st speed / 8 min 2nd speed

Oblique axis kneader (longer kneading)

140°F / 60 °C for improved kneading (PA) - 5 min 1st speed / 12 min 2nd speed

Likewise depending on the types of mixers the TB varies

Artofex mixer (plunging arm): 131°F - 140°F / 55 – 60 °C

Oblique axis kneader: 125.6°F - 129.2°F / 52 – 54 °C

Spiral mixer: 109.4 °F - 118.4°F / 43 – 48°C

You understand from the above that the TB is more suitable for professionals who adjust the TB to their equipment and their kneading time.

Note that the hydration of the dough is nowhere in the formula, the bakers integrate it with their experience in their "bacuses".

And now at home | forget the TB of professionals

Now when you see protocols circulating with TBs you will understand that this only makes sense with a very precise context.

You can use TB using the simple formula:

TB = 3 x Dough temperature

Here is what Fabrice COTTEZ (a French baker & Youtuber) of “Bakery step by step ” recommends

For bread to make at home

Target temperature between 73.4 °F - 77.0 °F / 23°C - 25°C

Manual kneading TB = 167.°F / 75°C

Kneading in a food processor TB = 147.2 °F / 64°C

To go a little further there are simple adjustments that you can use:

With a KitchenAid Artisan , hydration at 70%, kneading/kneading for 9 minutes this gives a temperature increase of 6.8 °F / 3.8 °C

With a KitchenAid Artisan , hydration at 70%, kneading/kneading for 15 minutes this gives a temperature increase of 13.7 °F / 7.6 °C

With a Thermomix , hydration at 70%, kneading/kneading for 5 minutes this gives a temperature increase of 13.7 °F / 7.6 °C

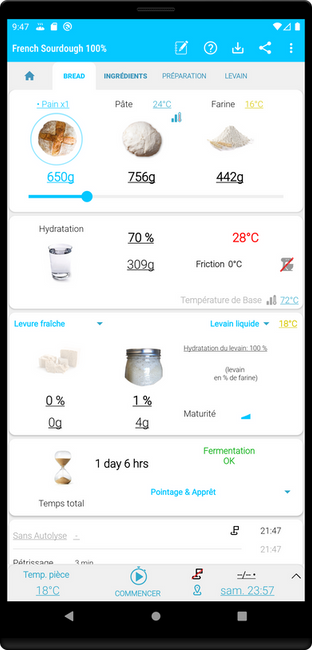

Personally, I opted for a 100% digital approach because it makes it possible to manage many cases such as fermentolysis or autolysis, and also fermentation times automatically . For this I created an ANDROID Application "Homemade bread recipe" which does the calculations very precisely.

Here's what it looks like visually

To return to the initial example (manual kneading in winter), on the left the TB method, on the right with the complete temperature model. We see that there is a 10°C difference between the two temperatures.

The question is who is right and my experience tells me that the method of a mathematical model is much more precise.

This is why one bakery = one TB for a recipe

The TB model is over 100 years old and remains purely empirical

A baker's TB is specific to his bakery (his equipment, his protocol)

Bakers adjust the temperature during kneading by “basinage” (adding water at a temperature to adjust the temperature of the dough and its hydration)

The hydration rate which is fundamental for warming up is not taken into account

A physical model takes into account the weight of the ingredients and their nature (heat capacity = inertia of temperature variation)

End-to-end temperature | the real life of dough

Until then the approach remains theoretical because the temperatures of the piece and therefore of the dough evolve. This is all the more true when autolysis is carried out (just after milling).

Here is an example of a protocol with temperature variations (the App works also in °F)

Protocol

1h30 autolysis

The target temperature after kneading is 75.2°F / 24°C

The kneading is in the robot (7 min)

Ambient temperature 68°F / 20°C

Analyse

The water temperature must be adapted to take into account the loss of temperature of the dough during autolysis

The application will start from the target temperature excluding the temperature increase during kneading (~5.4 °F / 3°C)

From this point the App will calculate the drop in temperature during autolysis (~2.7 °F / 1.5°C) and deduce the starting temperature of the dough after milling (72.7 °F / 22.6°C)

From this point the App can calculate the water temperature necessary to reach this temperature after milling

Knowing all the temperatures, the % of leaven, the hydration, the App calculates the proofing and proofing time.

Here is the result of the ingredients and their temperatures.

The distant origins | once upon a time there was a baker in winter....

The initial problem, what is the ideal temperature of the bread dough to ensure ideal fermentation over time depending on the ambient temperature and the type of bread I want to obtain.

In ancient times bakers used artisanal methods to prepare their bread, without the aid of modern tools to measure temperature. So they had to rely on their experience and intuition to know when the dough was ready to be shaped and baked. In winter the water used is deliberately lukewarm or even hot in order to have fermentation with acceptable times to sell your bread when the bakery opens. With the water leaving the well at 3 degrees Celsius and an ambient temperature at 6 degrees, it was necessary to heat the water but not excessively so as not to destroy the yeasts. Easy to tell with a thermometer, right?

Over the centuries, bakers have developed methods to gauge the temperature of ingredients and the fermentation process. Using the base temperature to measure the temperature of ingredients has become common practice, as it helps ensure optimal dough fermentation and consistent bread quality.

Emile Dufour is a French baker who was a pioneer in the use of base temperature in baking. He wrote a book entitled "The Modern Baker" (1919) in which he describes his method of calculating the base temperature in breadmaking. He was one of the first to use this method to evaluate the temperature of ingredients and the fermentation process, to ensure optimal yeast fermentation and consistent bread quality.

He also introduced the use of thermometer to measure core temperature, which allowed for more accuracy in temperature calculation. He also developed methods to adjust the base temperature based on weather conditions and the types of yeast used.

Emile Dufour helped popularize the use of base temperature in baking and his method is still used today by many professional bakers to ensure consistent bread quality.

>> Click on the picture to "know more" about Home BREAD RECIPES

______________________

Super helpful!!!